Building an Industrial Unified Namespace Architecture with MongoDB and Arcstone

April 27, 2023 | Updated: March 18, 2025

>> Announcement: Some features mentioned below will be deprecated on Sep. 30, 2025. Learn more.

The fourth industrial revolution, also known as Industry 4.0 is rapidly transforming the manufacturing industry. Leveraging I4.0 reference architectures and Industrial IoT technologies, factories generate more data than ever. Market analyst reports tell us that the global number of Industrial IoT connections will increase to 36.8 billion in 2025. As factories become more connected and data-driven, it is essential to have a unified and standardized approach for manufacturing data management.

In this article, we explain how MongoDB helps create a Industrial Unified Namespace (IUN) architecture that can act as a contextualized repository for data and information for all manufacturing assets.

Manufacturing companies have been leveraging the International Society of Automation’s standard 95 (ISA-95) to develop automated interfaces between industrial control systems and enterprise systems. ISA-95 provides a hierarchical model for interfacing and integration also known as the automation pyramid. Figure 1 shows the five levels of the automation pyramid.

ISA-95 was introduced in 2000 to improve communication and data exchange between different levels of the manufacturing industry. With the advent of Industrial IoT (IIoT), the limitations of the ISA-95 model have become increasingly apparent.

-

Lack of Interoperability: The model was developed for a more traditional, hierarchical approach to manufacturing, where there is a clear separation between operational technology (OT) and information technology (IT). In contrast, IIoT tries to blur the lines between OT and IT, with a greater emphasis on data interoperability and real-time analytics.

-

Limited Flexibility and Agility: The rigid and hierarchical structure imposed by the automation pyramid goes against Industry 4.0 concepts of flexibility and agility. The data captured by sensors must go through the SCADA and MES layers to reach the top level. This makes it difficult for manufacturers to adapt to changing production requirements and integrate IIoT technology into their existing systems.

-

Limited Scalability: The ISA-95 model was designed for a traditional manufacturing environment with a limited number of production lines and machines. However, with the growth of Industry 4.0, the number of connected devices and the amount of data generated has increased dramatically.

The automated pyramid does not easily scale to handle this increased volume of data and devices, leading to potential bottlenecks and inefficiencies in the manufacturing process. For example, if a new machine is added to the production line, ISA-95 requires significant changes to the factory IT and OT architecture, which can be time-consuming and costly.

Industrial unified namespace (IUN) architecture with MongoDB

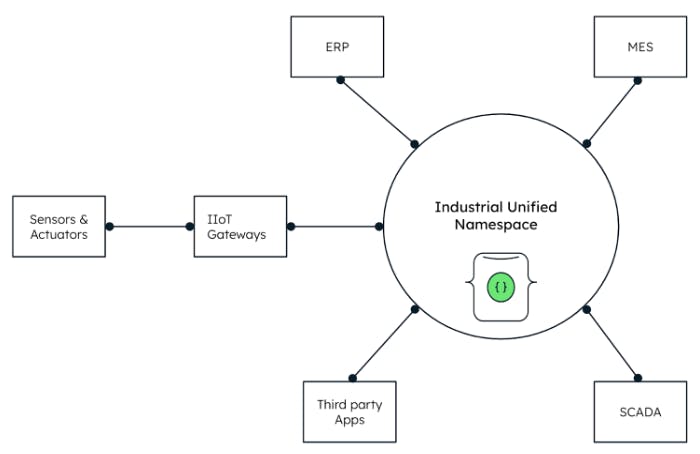

In order to overcome these challenges, we propose that manufacturers adopt an Industrial Unified Namespace (IUN) architecture leveraging MongoDB technology. Such an architecture will provide a single view of all manufacturing processes and equipment and will enable data interoperability between different layers of the ISA-95 automation pyramid. Figure 2 shows a conceptual diagram of the IUN architecture.

IUN follows an event-driven architecture topology where different manufacturing applications publish events in real-time (publishers) to the central MongoDB Atlas database. Application services subscribe asynchronously to the event types or topics of interest and consume them at their own speed (consumers). This results in a decoupled ecosystem allowing applications and services to act interchangeably to provide and consume data when and where needed in real-time. It is understood that many applications and services may produce and consume data at the same time.

MongoDB Atlas database plays a central role in the IUN architecture. The events can flow in through MongoDB Kafka Connector or Atlas Device Sync and MongoDB Atlas can aggregate, persist and serve them to consuming manufacturing applications. The core MongoDB Atlas database in this scenario provides a central repository for multiple independent event streams and the modern database helps to drive operational and analytical apps providing a complete end-to-end view of the production process.

Data modeling for industrial unified namespace

The document model is the most natural way to work with data stored in the database. It is simple for any developer to learn how to code against MongoDB, and as a result, industry surveys show it is wildly popular amongst developers. MongoDB provides flexible data modeling options to create a central repository for all factory production data.

-

Asset-centric data model: Focusses on the assets, for example machines, equipment, tools in the manufacturing process. This data model is useful for tracking the performance, maintenance, and utilization of assets.

-

Process-centric data model: Focuses on the day to day production processes. Such a data model is useful in optimizing the process flow and reducing bottlenecks.

-

Product-centric data model: Focuses on the products produced in the manufacturing process. This data model is useful for tracking the production and quality of individual products.

It is possible for a factory to have all three models at the same time. In fact, it is common for factories to use multiple data models and integrate them as needed to gain a complete view of their operations. For example, a factory may use an asset-centric model to track its equipment, and a product-centric model to track its finished goods, while also using a process-centric model to optimize its manufacturing processes.

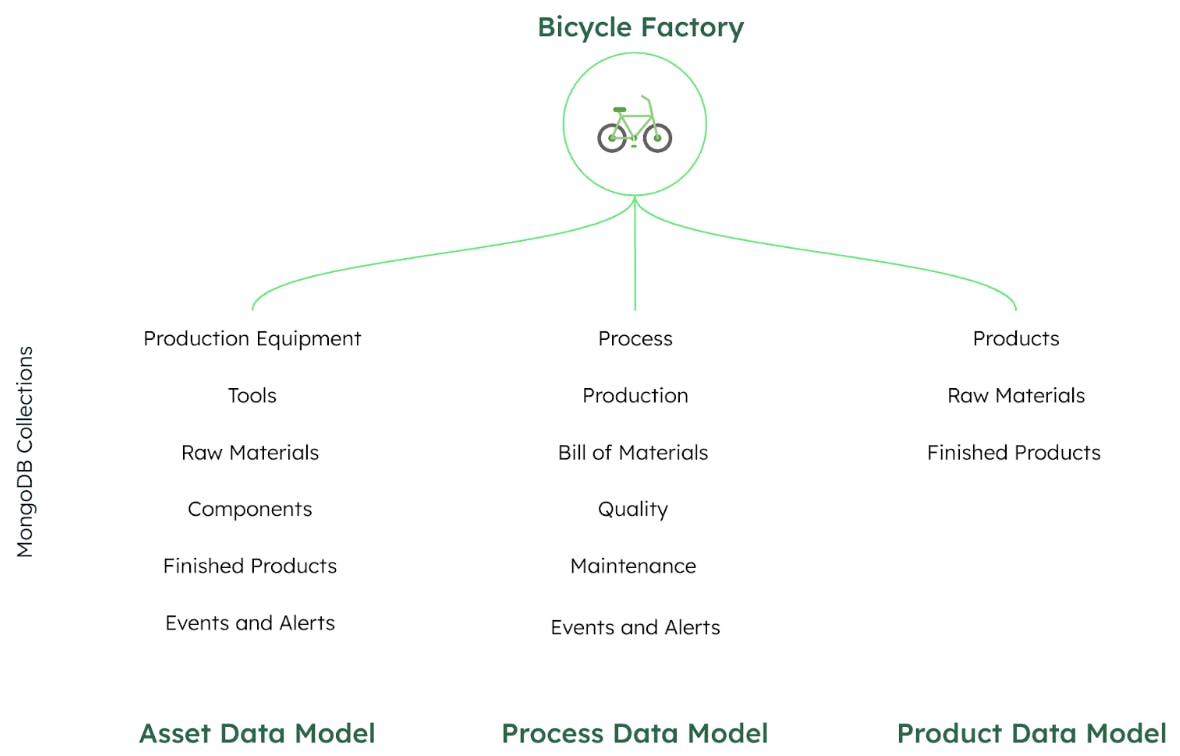

Let us take an example of a bicycle factory and look at example asset, process and product-centric data models. At a minimum, the following collections (Figure 3) will need to be created in the database.

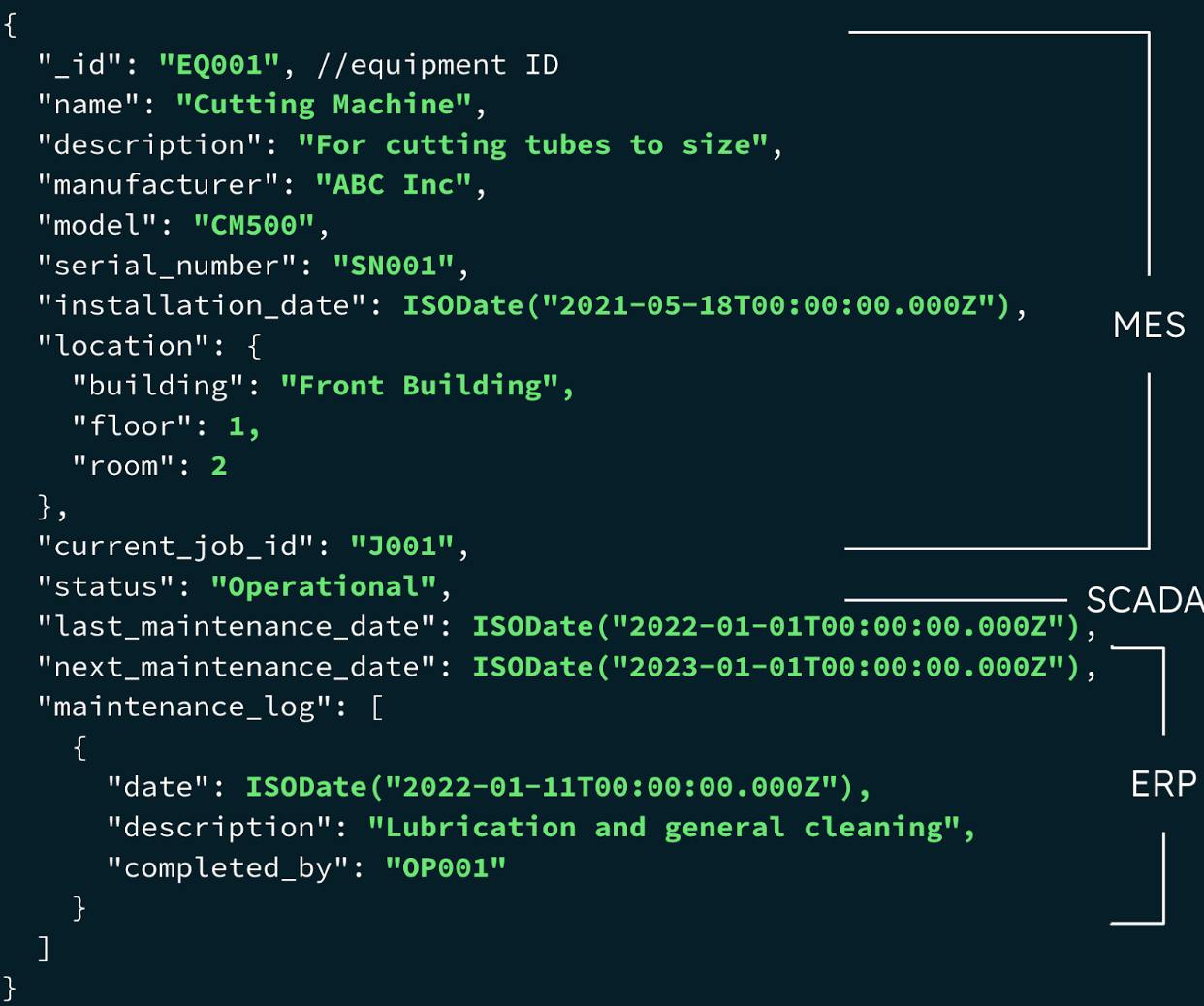

Each collection will have data coming from different sources such as Manufacturing Execution System (MES), IIoT Platform, and Enterprise Resource Planning (ERP) systems. An example document from the production equipment collection is shown in Figure 4. As it can be seen, the data comes from various sources and the MongoDB document model makes it very easy to combine this data together in one document generating a digital twin prototype of the machine.

Architecture for industrial unified namespace

Let us take our bicycle factory and create a solution architecture for the Industrial Unified Namespace. First, let us list down all the event producers and consumers. All these systems both consume and publish events:

-

IoT Gateways / Edge Server

-

Supervisory Control and Data Acquisition (SCADA) / Shop Floor Connectivity Platform (SCP)

-

Manufacturing Execution System (MES)

-

Enterprise Resource Planning (ERP)

Arcstone toolsets for smart manufacturing

Arcstone is a Singapore/US-based Industry 4.0 solutions company providing modular-based, next-generation MES alongside hardware integration and process orchestration toolsets. Arcstone delivers success to companies from diverse industries, including Global Fortune 500 companies, manufacturing companies, emerging facility management firms, and SMEs, globally.

Arcstone arc.ops MES contains 15+ modules for full operational management that can be custom tailored to specific requirements, and is built to be end-user configurable for easy intuitive use.

Arcstone understands that extracting data from legacy equipment is a challenging task. Therefore, they have created a low-code solution named arc.quire to handle the collection of raw data and streaming into a database for storage. arc.quire is used in tandem with a process orchestration tool called arc.flow to establish connectivity between arc.quire and the database, for example, MongoDB EA.

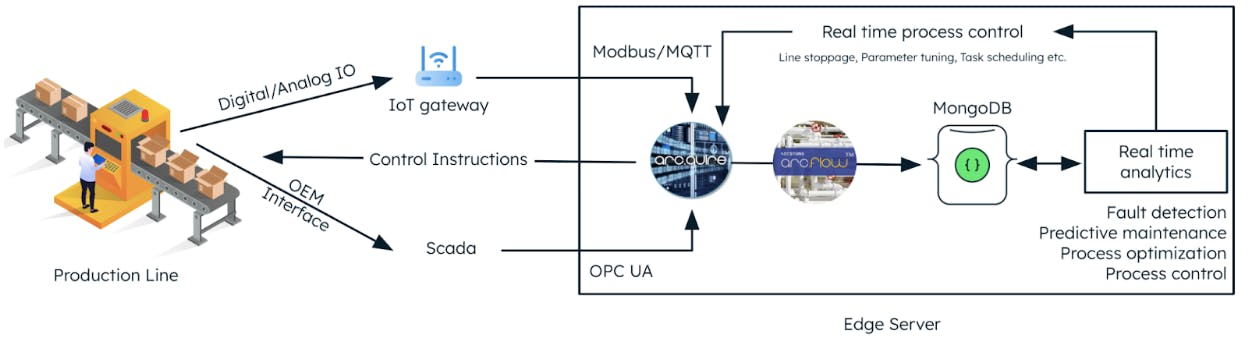

Depending on the connectivity interface exposed by the production equipment, SCADA or SCP software can connect to the equipment and push the raw events and alerts to the arc.quire running in the edge server. MongoDB’s Enterprise Operator for Kubernetes, gives the flexibility to run MongoDB as a container in resource-constrained environments such as our IoT edge server. Figure 5 shows how the edge server can be connected with the SCADA and IoT gateways on the production shop floor.

The edge server performs the following functions:

-

Aggregation of IIoT events and alerts via arc.quire

-

Real-time analytics such as machine fault detection, process optimization, and process control via the MongoDB aggregation framework

-

Transmitting control instructions back to the equipment via arc.quire

-

Raw data and analytical results storage in MongoDB

Edge servers act as one of the event producers for IUN. Using the MongoDB Kafka connector, events can be transmitted from the edge server to a centralized data repository in MongoDB Atlas.

Bringing it all together

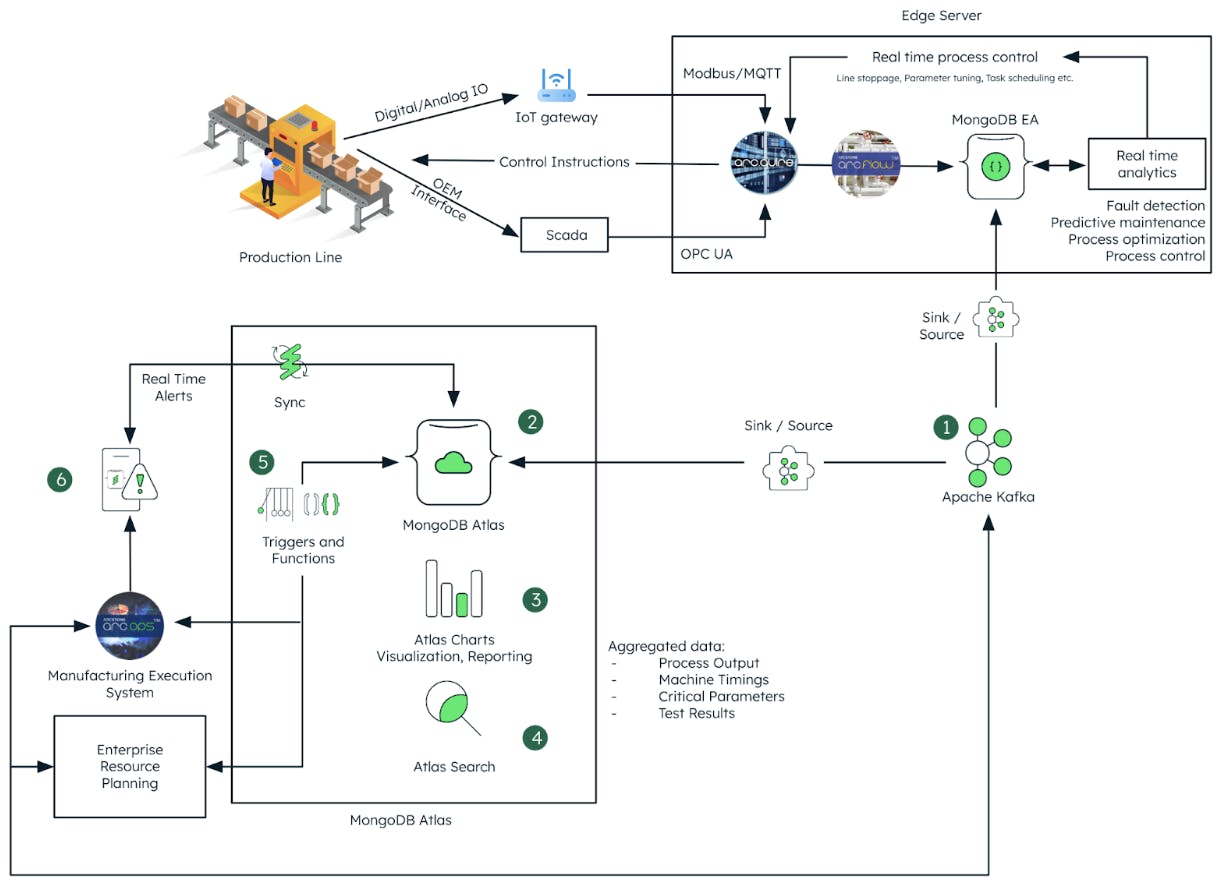

Figure 7 shows the complete technical architecture of the Industrial Unified Namespace with MongoDB Atlas modern database and Arcstone.

In this architecture, arc.ops MES, ERP, and edge server publish data to the message stream in Apache Kafka where the event queue makes the data available for MongoDB Atlas to consume via Kafka connectors [1 and 2]. Depending on the factory requirements around batch processing and scalability, Kafka can be replaced by a MQTT broker. There are multiple community backed and commercial libraries to push MQTT data into MongoDB.

The centralized database aggregates and persists events, enriches event streams with data from all sources, including historical data, and provides a central repository for multiple event streams. This enables applications and users to benefit from all data across all microservices and provides a unified view of the state across the factory. Atlas also leverages Atlas Charts for events visualization as well as Atlas Search for full-text search of events [3 and 4].

MongoDB’s Atlas Triggers provide a serverless way of consuming change stream events [5]. With Triggers, the manufacturer doesn't have to set up their own application server to run your change data capture process. Change streams flow change data to Atlas Triggers to create responsive, event-driven pipelines. Finally, Atlas Device Sync and Realm SDK can be leveraged to push real-time notifications and alerts to shop floor applications for users to consume.

Use cases

Predictive maintenance

IUN can be deployed as the foundation for predictive maintenance applications. Edge server streams time-series event data from the production equipment into MongoDB to drive machine-learning models that will detect equipment health and performance degradation trends.

The data is enriched using data streams about production jobs from MES. The factory can either repair equipment or swap it out for replacement parts before shutting down production lines. Atlas Device Sync can alert engineers on the shop floor to potential equipment failures, and help the company optimize the equipment maintenance strategy.

Operational data layer

The IUN architecture can be used to create a manufacturing Operational Data Layer (ODL). An ODL strives to centrally integrate and organize all siloed manufacturing IT/OT data and makes it accessible to stakeholders across the factory floor.

This ODL will combine data from both OT and IT sources into a single MongoDB Atlas database where Atlas Search and Charts can be used to analyze this data and drive actions on the shop floor. IUN captures any changes in source systems and streams them into MongoDB to keep the ODL fresh, and helps to update the source systems in real-time.

Conclusion

In conclusion, the ISA95 Automation Pyramid presents significant challenges for the manufacturing industry, including a lack of flexibility, limited scalability, and difficulty integrating new technologies. By adopting an Industrial Unified Namespace architecture with Arcstone and MongoDB, manufacturers can overcome these challenges and achieve real-time visibility and control over their operations, leading to increased efficiency and improved business outcomes.

Thank you to Karolina Ruiz Rogelj for her contributions to this post.

To learn more about MongoDB’s role in the manufacturing industry, please visit our Manufacturing and Industrial IoT page.