Greater uncertainty in global trade flows and black swan events, such as COVID-19, have challenged the linear supply chain business model. Digital technologies are being recognized as a key enabler for resilient and responsive supply chains. Supply Chain 4.0 is the reorganization of supply chain – plan, source, make, deliver, return and enable from a linear business model to an integrated one using concepts of Industry 4.0 (I4.0). In this article, we’ll explore how MongoDB, together with our industry partners in Singapore, help businesses integrate technological innovations into their operations to deal with diverse challenges posed by growing supply chains.

Supply chain trends and challenges

In today’s world of uncertainties and disruptions, manufacturing supply chains are becoming increasingly complicated and opaque. This is happening alongside organic supply chain evolution involving digitalisation, unified ecommerce and sustainability awareness. Disruptions are costly to deal with, often requiring manufacturers to expend large amounts of (and sometimes evitable) resources correcting them. Many companies were unprepared for the shockwaves from COVID-19 global crisis and realized that they should not take the supply chain for granted and they must invest in digitizing their supply chain operations.

In recent years, the investment in digital technologies for supply chain planning and execution has increased considerably. The emergence of Cloud Computing and the Industrial Internet of Things (IIoT) has promoted new opportunities for the supply chain and logistics domain. For example, real-time, cloud-based logistics and transport management systems have made logistics services more responsive and efficient, especially for small and medium-sized companies. However, supply chain management is much more complex than just logistics tracking. A reliable Supply Chain 4.0 platform should have some of these capabilities:

End to End Visibility: Aggregates data from various systems supporting supply chain planning and execution processes (e.g ERP, MES, WMS, TMS) and provides a single view for monitoring supply chain performance in real-time.

Decision Making Support: Contains tools and algorithms to support decision making for operations such as production scheduling, inventory assignment and order fulfillment optimization etc.

Disruption Prediction and Management: To be able to predict anomalies and respond in time upon major disruptions events by orchestrating tools for network simulation, production re-planning etc.

There are certain challenges associated with building a Supply Chain 4.0 platform that can enable above mentioned capabilities.

Data Collection and Privacy Challenges: Brand owners need the ability to track products, raw materials and goods across the supply chain to get a clear picture of inventory and supply chain overall health. They can use this data to predict and manage supply chain disruptions and risks. Building this ability is a daunting task as it requires sharing data between supply chain tiers while navigating the data privacy and security risks to get real-time global visibility across all supply chain nodes. A federated infrastructure might be the answer where the private raw data is kept locally and transformed data is synced with the cloud.

Data Modelling and Compatibility Challenges: A supply chain 4.0 platform must cater for the integration of the huge number of devices and services across the entire supply chain. These services and devices will transmit varied data in large volumes. This poses a data modeling challenge where a heterogenous data store is required to store this large amount of structured and unstructured data together.

Real-time Analytics Requirements: Supply chain real time use cases such as delivery dispatching, production scheduling, inventory management and logistics tracking requires tools and APIs that help companies build more sophisticated queries against live data of any shape and structure in addition to mechanisms to separate operational from analytical processing so the application doesn’t slow down, along with the ability to land insights close to users.

With these challenges in mind, the A*STAR Advanced Remanufacturing and Technology Centre (ARTC) initiated a Supply Chain 4.0 Program with other partners, to develop digital and automation solutions to meet businesses’ demands for technologies to make supply chains more agile, resilient, and secure. A*STAR also opened a Supply Chain Control Tower, to testbed these solutions with partners. Supported by research partners, the initiative has attracted over 50 companies from across five sectors (aerospace, fast-moving consumer goods (FMCG), pharmaceuticals, precision engineering, and semiconductors), including multinational companies and local small and medium enterprises (SMEs). Together with other Supply Chain 4.0 partners, MongoDB is supporting ARTC in developing an easy-to-use database platform, ORCA, that can enable data sharing and processing across and within enterprises.

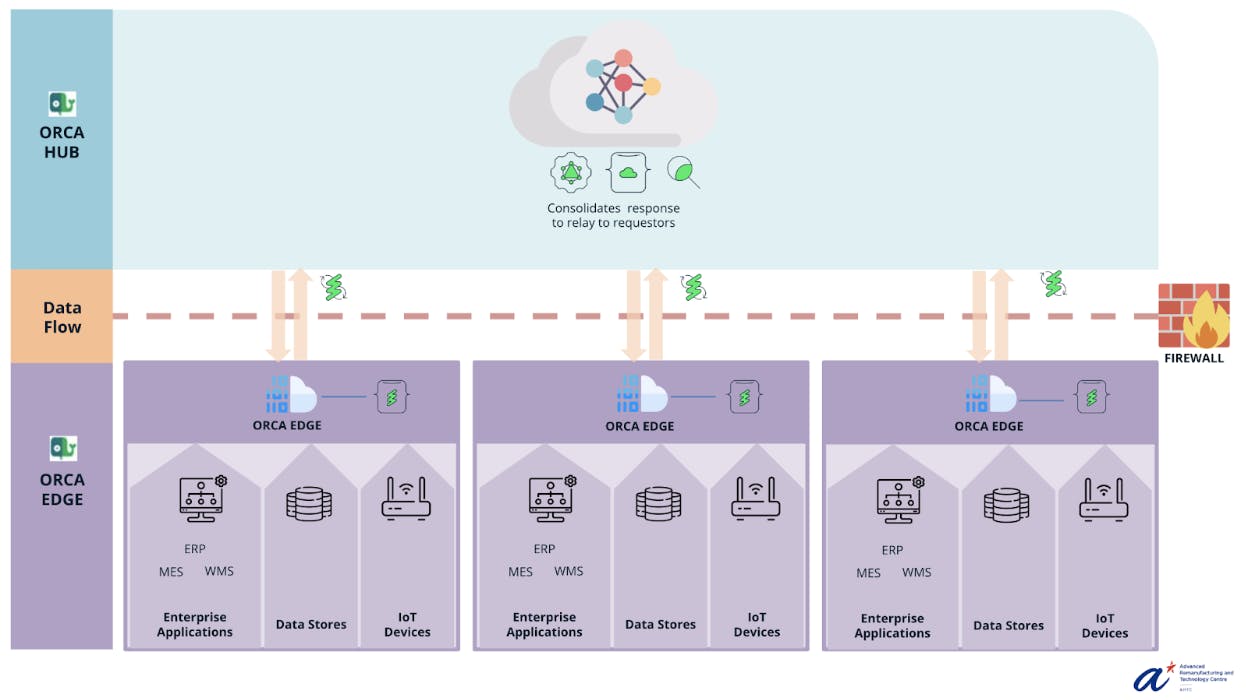

There are two main components in ORCA: ORCA hub and ORCA edge. ORCA hub takes care of cross-enterprise information sharing and is built on federated database architecture in which a collection of independent database systems are united into a loosely coupled federation in order to share and exchange information. The approach would be a Hybrid between Cloud and Local resources. The cloud will only keep the metadata, models, references while keeping actual data locally to the organization eliminating massive data migration and data privacy concerns between member organizations.

ORCA edge, on the other hand, takes care of enterprise information aggregation and enables integrating legacy SCM systems (ERP, TMS, WMS) via a novel data exchange middleware. It provides a seamless and synchronized communication environment for different simulation platforms and risk management.

MongoDB Atlas has been leveraged among other technologies to develop this easy-to-use data platform. The document model makes it possible for the developers to model heterogeneous data coming in from multiple sources in the supply chain. Realm database acts as the persistence layer in ORCA edge and filtered collections are synced with ORCA hub database via Atlas Device Sync.

The ORCA platform can collate data from multiple sources in the supply chain, as well as enable quick information sync and search. The technology developed by the Supply Chain 4.0 Program could help companies mitigate supply chain disruptions.

Visit our Manufacturing hub to learn more about innovation in the manufacturing space.